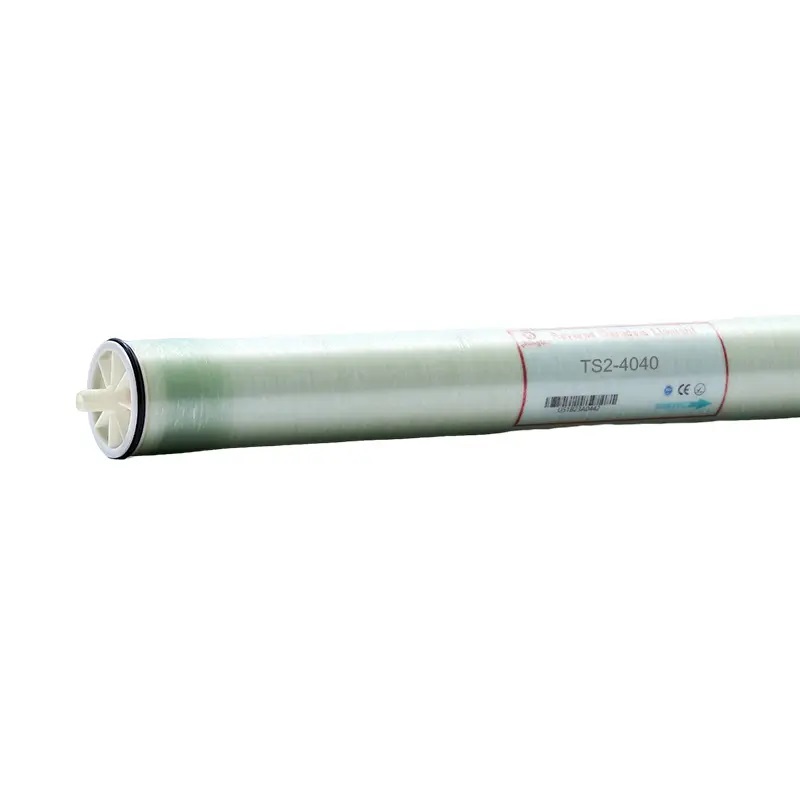

“Red film” low-energy consumption series

Product characteristics

The unique secondary interface polymerization technology makes the molecular structure of polyamide more stable. At the same time, the advanced surface grafting film making process further modifies the molecular structure of polyamide. The membrane surface tends to be more electroneutral, and metal cations are not easily adsorbed on the membrane surface, enhancing the pollution resistance of membrane components. At the same time, the cleaning and recovery performance of the membrane after being contaminated is also greatly improved.

SPECIFICATIONS & PARAMETERS

|

Model |

Stable desalting rate(%) |

Minimum desalting rate(%) |

Mean water productionGPD(m³/d) |

Effective membrane areaft2(m2) |

passageway (mil) |

||

|

TH-ECOPRO-400 |

99.5 |

99.3 |

10500 (39.7) |

400(37.2) |

34 |

||

|

TH-ECOPRO-440 |

99.5 |

99.3 |

12000(45.4) |

440(40.9) |

28 |

||

|

TH-ECOPRO(4040) |

99.5 |

99.3 |

2400(9. 1) |

85(7.9) |

34 |

||

|

test condition |

Test pressure

Test fluid temperatureTest solution concentration NaCl Test solution pH value Recovery rate of single membrane element Range of variation in water production of a single membrane element |

150psi(1.03Mpa)

25℃ 1500 ppm 7-8 15% ±15% |

|

||||

|

Limit usage conditions |

Maximum operating pressureMaximum inlet water temperature

Maximum inlet water SDI15 Free chlorine concentration in influent water PH range of inlet water during continuous operation PH range of inlet water during chemical cleaning Maximum pressure drop of a single membrane element |

600psi(4.14MPa)

45℃ 5 <0.1ppm 2-11 1-13 15psi(0.1MPa) |

|||||